|

Our very own Mark Degan spoke with CR80news regarding the current trends in ID Card Accessories.

It comes as no surprise that students often damage their ID Cards, so protecting them is always a smart move. In this CR80 news article, Degan explains the best practices to protect your ID badge over a long period of time. From lanyards to badge holders, this article covers everything you need to know about ID Accessories in 2018. Click the button below for the full article on CR80 News.

0 Comments

Recently came across an informative article regarding consumables and how they should be managed within the higher education sector. To learn more about protecting your ID Badge Printer consumables like unpersonalized cards & badges, color ribbons, laminates and more click on the image here: About ColorID: Founded in 1999, ColorID is one of the world's largest integrators of identification technologies and solutions for security, identification, access control, biometrics and transaction management. Though primarily focused on specific North American markets, ColorID also provides these solutions to organizations around the world. The company’s highly knowledgeable and customer-focused sales and product management teams help customers select and integrate the best products and services from the identification industries most innovative and preeminent manufacturers. The company’s engineering team also provides exceptional support for the life of all products. Contact ColorID at 704-987-2238 or toll free in Canada and the US at 888-682-6567. Visit ColorID on the web at: www.colorid.com or email ColorID at [email protected].

ColorID's most recent installation of the Biometric Dining Solution installed at Virginia Commonwealth University received national spotlight this past week.

NBC.com posted the following video as it reviews the system and the technology behind it . Iris cameras offer VCU students faster entrance to Shafer Court By Brian McNeill University Public Affairs 804-827-0889 [email protected] Thursday, July 30th 2015 Hungry Virginia Commonwealth University students will have a speedier – and more futuristic – option for entering Shafer Court Dining Center this fall. The university on Wednesday installed two iris cameras that will allow meal plan holders to use their eyes instead of having to swipe their IDs to access the dining hall. "Students won't need their ID to enter the dining center anymore," said Stephen Barr, the director of campus services who oversees VCU Dining Services. "With iris identification, it’s as simple as a camera taking a picture of their eyes and two seconds later they walk through." “With iris identification, it’s as simple as a camera taking a picture of their eyes and two seconds later they walk through.” The new system, which is voluntary, is meant to serve as something of an express lane for students. "We thought it'd be a nice service for students to help everybody get through at peak times," Barr said. Plus, he added, the iris cameras will give students who lose their IDs over the weekend the ability to still access their meal plans even though the ID card office is closed. "There currently isn’t a mechanism for students to get a replacement ID [over the weekend] so they can access Shafer," Barr said. "So how do they eat over the weekend? In the past, they've had to come out of pocket. Now they don't have to. This backup lets them get into Shafer so they can eat.” Cashiers will remain in place for those who choose not to use the iris cameras, as well as for visitors and others entering Shafer Court. The iCAM 7100 iris cameras, made by North Carolina-based ColorID, take a high-definition photo of the user's iris and then identify 220-plus unique points. It then generates a number, which is associated with that individual meal plan holder's iris. "We don't keep pictures of your iris," Barr said. "It's just a number, just like your ID. Your ID has a unique number that ties it to you." To sign up interested students, the university will have stations set up at Shafer Court and elsewhere during the first couple weeks of the fall semester. The iris cameras are an example of how biometric credentials are being increasingly embraced. Many people use their fingerprints to unlock their iPhones, for example. And the Cary Street Gym uses a fingerprint – and soon a handprint – scanner to verify the identity of students and subscribers accessing the gym. VCU Dining Services chose to go with iris cameras, Barr said, because it is reliable and does not require touching – which is especially important before a meal. "We're going to continually improve access to Shafer and see if there are other places [on campus] that we can expand this kind of technology to, as well," he said.

Check out the SD460 Tactile Impression Feature by Entrust Datacard. This new feature offers the latest anti-counterfeiting technology.

What to do when it's time to replenish card stock

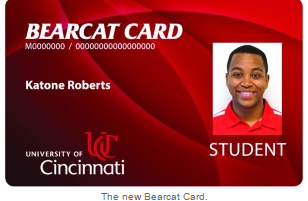

CR80News & ColorID article series continues... Every university has to manage its card stock supply, and though it's not the most exciting task for a card office to undertake, being left without a sufficient supply of cards can bring a university's card issuance to a grinding halt. Depending on the size of the institution, the type of credential, and even the time of year, replenishing card stock is more of a process than you may think. ColorID's corporate marketing manager, Mark Degan, offers his insights to better explain the factors that a university should consider when it comes time to restock. Keeping stock When it comes to card stock supplies, the first consideration for any university card office should be the amount of card stock needed to keep the operation running smoothly. "Depending on the university's orientation sizes, as well as the functions that they are using their ID cards for will help determine the amount of card stock it should keep handy," explains Degan. "I would suggest having at least six months worth of card stock in house at any given time." Housing six months worth of card stock should provide a significant cushion for a university to accomplish its average operations, but it is also important to account for potential abnormalities in card stock consumption. "A number of issues can come up that could increase your card consumption," says Degan. "The most common are large orientation classes, re-carding, card stock failure, bad batches or even an ID printer malfunctioning and requiring reprints." Degan explains that the size of the institution may also play a role in the restocking process, as larger universities do usually have a larger replenish size. Alternatively, larger universities can order more frequently rather than placing a single, larger-quantity order. Know your lead time In addition to the many operational challenges that a card office may face, another key consideration for replenishing card stock is lead time. As Degan explains, a card office must take lead time into account because delivery time frames will vary depending on the type of card stock. "Non-custom, non-technology, or blank, card stock is usually available in sleeves of 500 in a number of options and varieties," explains Degan. "For blank card stock, the standard lead time is one week, and if for some reason it isn't in stock, a new order could take up to four weeks." Next on the list is custom, non-technology card stock. "These card stock orders usually take between 2-4 weeks, but in the summer months, universities should assume 6-8 weeks," says Degan. According to Degan, non-custom, technology card stock typically comes in sleeves of 250-500 and offers a number of options and varieties. "Standard lead time for this card stock is 1-2 weeks, but if it's out of stock a university should expect 4-6 weeks for manufacturing throughout the year and 6-8 weeks during the summer months," he adds. The lengthiest lead time can typically be found with custom, technology card stock. As Degan explains, these orders routinely take around 4-6 weeks, but in the summer months can balloon up to 6-10 weeks. Despite their varying lead times, Degan does explain that the type of card stock does not affect the overall order quantity, provided the university can afford to wait for the shipment to arrive. It's for this reason that planning ahead is crucial. Time is of the essence As previously mentioned, the time of year can factor into the amount of time it takes to process an order. With this in mind, Degan offers some advice for planning ahead. "The best time of the year to order card stock is from October to April," Degan explains. "After spring comes around, and throughout the summer months, lead times always increase because some universities forget to place their orders earlier, or have just realized they opened their last box of cards." Degan places a hard deadline on a restocking order. "The absolute latest that a university card office should wait to reorder card stock is six months worth of card supply," he says. "Waiting any longer than that will result in longer lead times and could make life a little more stressful." "We send our customers emails throughout the year with accurate lead times so they can plan ahead," says Degan. "Lead times can change very rapidly so be sure to ask at the time of your order what the current lead time is and if you need cards by a certain date to relay that to your provider." Ace up your sleeve Running out of card stock will bring any card office to its knees, halting all card issuance in its tracks. Knowing the lead time for your university's type of card stock is vital. While replenishing card stock likely isn't a daily thought for card office administrators, it's nonetheless a task worth considering. With just a little bit of planning in advance and an understanding of your university's needs, a card office can steer clear of catastrophe and avoid the bottom of the deck.

How universities are using biometrics in the dining hall.

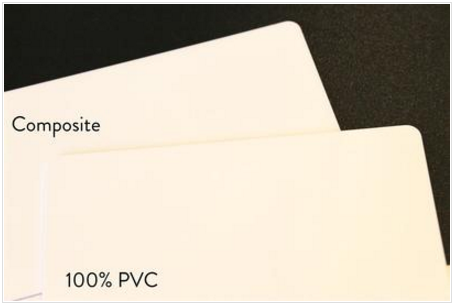

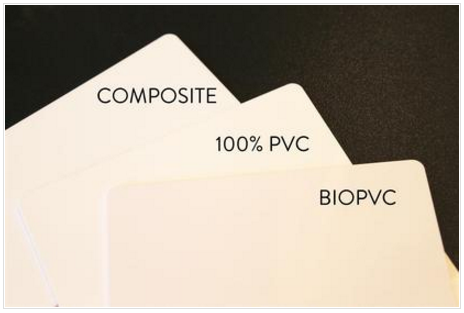

For universities nationwide, getting students through the dining hall doors and to their daily meals is a constant struggle that requires a delicate balance of student convenience and throughput. Biometric applications have garnered demand in a number of locations across the contemporary college campus, particularly those locations where students don't want to carry their cards. But biometrics has extended beyond rec centers, athletic facilities and team locker rooms, as more universities are deploying the technology at campus dining halls. While a vast majority of universities use the campus card to facilitate dining hall entry, some institutions have decided to leverage biometrics at the dining hall door, enabling the students to be their own meal ticket. Today's Special "The dining hall application continues to be a hot topic for universities," says David Stallsmith, director of product management at ColorID. " Attendees at NACCU, NACAS, UBTech and several other higher education conferences have expressed great interest in biometrics technology this past year." As the technology continues to evolve, with both scanner hardware and matching algorithms becoming more robust, biometrics seems a viable alternative to the traditional campus card. According to Stallsmith, there are a few primary factors that contribute to the performance of a biometric dining system. "There's the quality of the sensors, the security of the matching algorithms built into the supporting software and the location of the stored templates - on card, in database or on device," says Stallsmith. "Moreover, you can also designate the the number of factors required - biometric alone, biometric and card or biometric and PIN." As Smallsmith makes clear however, there will always be a place for the student ID card. "We don't believe campuses are ready to ditch ID cards, but there are certain applications where biometrics seem to work better and faster than mag stripe or contactless cards," Stallsmith explains. A Menu of Modalities In addition to its hardware and software evolution, biometrics as a medium has grown as well. Biometric modalities now range from the standard fingerprint to advanced vascular biometrics, keystroke recognition and even gait. Modality is just one of the many factors that contribute to the success of a biometric implementation, but it's an important consideration, nonetheless. What modality, then, is best suited to the university dining hall? ColorID offers fingerprint and palm vein sensors, as well as an iris recognition solution. Stallsmith believes it's the latter that holds the most promise in dining applications. "Of the current biometric modalities, iris recognition is usually the fastest and most accurate, especially for populations over 10,000," explains Stallsmith. "Iris is a one-to-many method of recognition, as opposed to palm vein or fingerprint that typically still require a one-to-one match." "The algorithms for fingerprint and palm vein aren't fast enough to match against a larger database, and thus requires a PIN or card to match against a template," adds Stallsmith. For dining hall applications where convenience is key, carrying an additional factor of authentication in the form of an ID card or a memorized PIN doesn't enhance the experience. One-to-many matching means that the iris systems can yield a match much quicker, making it an ideal modality for populations of 2,000 or more.Iris authentication is achieved by taking pictures of the eye and using the iris patterns to create unique numbers, called templates. These are then matched against all the templates in a database. Stallsmith explains that a typical iris identification transaction is completed in just two seconds, from approach to approval. "Across the board, we have found that iris recognition performs better than other modalities, though iris systems tend to be slightly more expensive," Stallsmith adds. An ever-present consideration, cost will likely be a sticking point for most institutions considering a biometric deployment at the dining hall. "High-quality biometric readers range anywhere from $800 to $3000, depending on the type of scanner," estimates Stallsmith. "There can also be software and integration costs." Stallsmith goes on to explain, however, that when used in high-throughput applications, sensor costs can be quickly distributed across the larger number of users.In practice, iris seems to be gaining momentum in the campus dining space.George Mason University has installed iris systems in all campus dining halls, and Stallsmith estimates that another six universities are in the planning and pilot phases for similar projects. At Georgia Southern University, more than 10,000 students have enrolled in an iris-based transaction system. To date, the university has logged some 1.2 million iris-based transactions since the biometric dining solution's implementation in the fall of 2013. Blending Flavors Selecting an affordable biometric solution is still only part of the concern for university administrators, as the integration process can be complicated without the proper preparation. "Biometric devices are typically built for access control and are designed to output a previously stored card number upon identification of each person," explains Stallsmith. "For implementation, you have to understand how to convert these card numbers into data that can be read by your university's POS terminals and other online devices." "Essentially, if the device has an input, we can get the right kind of data into it," says Stallsmith. "Once the POS terminal or card system receives the card number, the validation process is the same as it would be for a mag stripe or contactless card." "Each user's card number is entered in the biometric system during enrollment, which can normally be done while the ID card is being printed," he adds. Soup's On So long as there are hungry students on campus, there will be lines at the dining hall. Being able to get students through the door and to the dinner table as quickly and efficiently as possible, then, will be a vital concern. Meanwhile, the use of biometrics on the contemporary college campus continues to grow in both adoption and variety of use. As iris, fingerprint and other modalities continue to evolve, dining hall applications could be the latest to benefit from the technology. CR80News Article :http://www.cr80news.com/2014/11/05/be-your-own-meal-ticket?issue=cr80news_20141105 Check out the latest ColorID & CR80News joint article series below or by clicking the following link. Pick a card, any card / A definitive rundown of cardstock materials and considerations. "Another way to tell if you have a composite cardstock is by bending a card back and forth," says Brooks. "Regardless of how many times you bend a card back and forth it should not tear in half as a PVC card will." Quantifying durability is a challenge, but lifespan can give an indication. "One manufacturer's testing shows between 3 and 8 times longer life than PVC for their different composite formulations," he says. Play to your hand Understandably, there are cost differences between the various materials as well, adding another layer to the decision-making process. "Cost differences can vary depending on the manufacturer and the formulation they use for their composite material," says Brooks. "On average, a composite card will cost twice as much as 100% PVC." Cost and user wear and tear aside, a university has to print its cardstock. This is yet another factor to mull when selecting the material. "PVC cards are very well suited for direct-to-card (DTC) type plastic card printers, while Composite cards are better suited than PVC for Reverse Transfer printing and overlaminating," explains Brooks. "This is due primarily to the higher amounts of heat that are generated from these processes." "PVC cards tend to warp easily in high-heat conditions, and although it's possible to print lamination on PVC cardstock, I don't suggest this route," Brooks adds. There are a number of considerations that a campus card office must navigate when delivering a robust and functional student credential. For instance, choosing the right printer, card technology and even the proper printing method are all vital concerns, but there is another decision that must be made that precludes each of these factors. The cardstock itself comes in a number of different flavors, each carrying benefits and limitations. As ColorID's project manager, Todd Brooks explains, selecting the right card material is a decision worth contemplating. Ante Up Campuses actually have options, and Brooks offers his list of things to things to consider. "A university must first consider the technologies it needs in its card," says Brooks. "Options include contact smart card chips for logging onto computers, contactless and prox chips for physical access, and magnetic stripes for payments and other uses." Brooks explains that the type of technology deployed on the card will affect what composition - or card material - you choose. "If you utilize a contact or contactless chip, I recommend a Composite or PC (Polycarbonate) cardstock because of how durable those materials are," Brooks explains. "Mag stripe users generally assume PVC is sufficient, however Composite cardstock will provide a much longer life span and thus a lower number of reprints." Despite the overwhelming popularity of PVC and Composite cardstock, there is an array of material options out there today. Brooks provides his top materials in order of popularity:

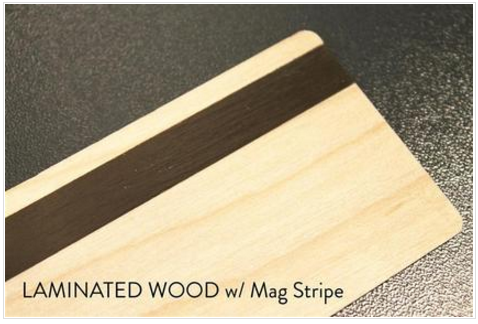

When it comes to telling the difference between the various materials, particularly PVC and Composite, some have questioned if there is a difference at all. Brooks explains that each card material does have its own characteristics. Plastic cards are made from laminated sheets of plastic, and in the case of PVC cards, each of these sheets are 100% PVC material. For Composite cards, some of the sheets are made up of a polyethylene terephthalate (PET) polyester resin material. "Depending on the formulation needed (60/40, 80/20, etc.), that will adjust the type of layer used and thickness of each layer," says Brooks. "Regardless, composite cards can dramatically increase the life of the card and are fair superior to 100% PVC cards." 'Its possible to tell the materials apart in other ways as well, and depending on the university desired specifications, this may be worth considering. "With PVC cardstock, you shouldn't be able to see the layers on the edge of the card and it should look like one solid core piece of material," explains Brooks. "Also, when handling a PVC card you should be able to snap the card in half after bending it back and forth over a dozen times or so. Likewise, Composite cardstock has its own telling features. "You may be able to see the layers," says Brooks. "It depends on if your manufacturer uses the same color tone materials or if they use the standard coloration the materials come in." As Brook explains, the color of the layers does not impact with the durability, as Composite cardstock will always be more durable than PVC. Shuffling the deck Let's lay all the cards on the table. Different card materials, by their nature, are better suited to certain deployments than others. Here's a definitive rundown. "Composite cardstock, regardless of its blend, will not be affected by severe cold or heat conditions, while at the same time its life span is very good at 4 or more years," explains Brooks. "The only con is that some Composite materials render blank, white cardstock more of a tinted color instead of true white." Alternatively, Composite's close competitor, 100% PVC cardstock is not so robust against extreme elements. "Under high heat or cold conditions PVC can became overly flexible or extremely brittle," says Brooks. "The average life span of a PVC card is lower at two to four years." Polycarbonate cardstock, PC for short, is a relatively new option to the masses, according to Brooks. "Polycarbonate is stronger than Composite, however you will need to utilize a Reverse Transfer or Laser Engraving printer, as Direct-To-Card printing will not work on this card surface," says Brooks. Even smaller universities routinely issue tens of thousands of cards. That's a lot of plastic. While there are options for the environmentally conscious campus, these materials have been not been used to wide degree on campus and care should be taken to learn about their limitations before selection. The first is recycled cardstock, which as Brooks explains, is exactly what it sounds like. "Semi-used or non-spec'd cardstock is shredded and reused for this stock," he says. "It's similar to 100% PVC in terms of wear and tear, though the coloration is not white, it features more of a grayish look." Another green option is biodegradable, or BIOPVC cardstock. "Biodegradable cardstock is essentially a 100% PVC cardstock but the polymers that bind the PVC granules together are biodegradable," explains Brooks. "The PVC will never decompose, but the card will revert back to a granule state after 5-7 years in the ground." Delving further into the biochemical realm, there's PLA cardstock. Short for polylactic acid, PLA cardstock is a plastic material derived from cornstarch. "Corn based cards are not 100% bio-gradable, they're estimated around 85%. Normally, the core of the card is PLA and the outside shell is PVC," Brooks explains. "Wear and tear is similar to both BIOPVC and 100% PVC, but is also affected by severe hot and cold conditions." But if science isn't your thing, and you have a flair for the old school, there's always wood. Sure they're flammable and not exactly the best option for regular, daily student use, but the wood card is a niche option nonetheless. "Believe it or not, wood cardstock is available in both laminated and non-laminated versions," says Brooks. "We do not suggest utilizing wood cards inside your ID printer because of the heat the printer generates. Wood cardstock does, however, make a great short-term ID for conferences or special events." Turn up trumps

While there are a number of factors to consider when issuing a quality student credential, selecting the proper card material is one of the foundational decisions that must be made. With a wide variety of material options - each with their own set of strengths and weaknesses - it can be easy to simply flip a coin and go with the first material you see. But cost, durability and environmental issues of plastic credentials make this decision one worth contemplating. Whether to pre-print static areas of the institution's cardstock or rely on desktop printers to add all the elements on the fly is an important and debatable topic. There are tangible benefits - both in terms of the cards themselves and the process of issuing them -for a university that pre-prints its cardstock. But there are also drawbacks related to flexibility and timeliness.

ColorID's higher education & K-12 market manager, Tim Nyblom, spoke with CR80News about when pre-printing card stock is appropriate, why a university should consider it, and most importantly, how they should do it. Why pre-print? "Pre-printing is for universities that want a professional-grade cardstock and recognize that cost is not the primary concern," says Nyblom. "It creates a longer lasting card with superior color quality and provides a more robust final product than a standard desktop printer can yield." Professional aesthetics and longer lifespans aren't the only benefits, however. As Nyblom explains, pre-printing enables a university to expedite the issuance process, as there is less area for the printer to cover, allowing the ID card to be completed quicker. "Pre-printed cardstock using lithographic or digital presses is made via layers and the artwork layer is protected by a thick clear sheet of laminate," explains Nyblom. "Desktop ID printers print on the outside layer of a manufactured card and thus is prone to fading over time." Pre-printed cards offer a noticeably better print quality that cannot be matched using a desktop ID printer. "Pre-printed cardstock gives you 3,000 DPI (Dots per square inch), whereas desktop ID printers can only reach 600 DPI," he explains. "It also allows a university to utilize the Pantone Matching System to recreate their brand's specific colors." More than one way to pre-print Deciding whether or not to pre-print is just the first step. Next is choosing the printing method and whether to do the work in house or outsource to a third-party vendor.As Nyblom explains, there are three pre-printing methods that a university can choose from: lithographic printing, high definition/digital press printing, and dye sublimation. "In house pre-printing is usually done with a high issuance desktop ID printer utilizing the dye sublimation method," explains Nyblom. "This method is good when low quantities, single-sided printing or monochrome (one color) printing is needed." Nyblom stresses that the in-house method using a desktop dye sublimation printer is not to be confused with outsourcing via lithographic or digital press printing. "Once a card has passed through a desktop ID printer, you do not want to print on that same side again as the print head and ribbon can stick to the already printed cardstock," he says. In the campus card market where card fronts are almost always personalized to the individual, in-house dye sublimation pre-printing is typically only considered for static card backs as a time saving measure. This is not the case, however, with other printing methods. "Having your static design pre-printed via a lithographic or digital press first and then printing your variable information with your desktop ID printer is the best route to take," says Nyblom. Variable information often includes elements such as cardholder photo, name, ID number and barcode. Nyblom explains that lithographic printing is ideal for large quantity runs of 5,000 cards or more. The printing is of an extremely high quality, offering a 3,000 DPI resolution, and has the ability to print a large number of colors, including specific spot colors - often referred to as PMS or Pantone colors. "In this process, the cards are manufactured from large plastic sheets consisting of 28, 56 or 70 cards per sheet that are then cut down into individual cards," explains Nyblom. "The cards are built up through different layers of materials including clear plastic, PVC and PET." Another avenue is High Definition printing, otherwise known as Digital Press printing. This method is ideal for low to mid-level quantities from 500 up to 10,000 cards, while still offering up to 3,000 DPI print resolution. The main difference from Lithographic, as Nyblom explains, is that digital press plastic sheets typically consist of only 21 cards per sheet. "Universities that opt for digital press can still utilize multiple colors for their cards and incorporate Pantone colors for their unique and custom branding," he adds. While the other methods mass produce printed cardstock, dye sublimation printing is done one card at a time on pre-assembled ID cardstock, and is generally used for low-volume printing. "The dye sublimation process will apply color to the cardstock one color at a time: yellow, magenta, cyan and then black," says Nyblom. "Since this process only uses a four color process, it is not able to match PMS (Pantone) colors. It's a process that is excellent for quick turn projects, low quantities and variable printing jobs." The case against pre-printing Still, pre-printing cardstock may not always be the answer. "If a school is just launching their ID card program, I'd suggest starting off with utilizing a blank cardstock first," Nyblom says. "This will allow them to adjust and change their card design to what works for them. After the university gains more experience and has identified what matters to them, then I would suggest migrating to a pre-printed cardstock." Traditionally, the arguments against pre-printing highlighted the lack of flexibility it carries. Once a large quantity of cards is ordered and printed, changes to card design are not possible. If these changes are mandated any remaining inventory must be discarded. Additionally, inventory management becomes more crucial. If cards run out during the middle of an orientation session, it can cripple the issuance process and take weeks to replenish supplies. Finally, for small quantity issuers pre-printing may not be cost effective despite its benefits. Final thoughts Pre-printing is a great way for a university to expedite its card issuance, while also boosting the overall quality of its campus IDs. By understanding the pre-printing options that are available and the institution's specific requirements, pre-printing can offer a significant value add to campus card services. |

Categories

All

Archives

July 2020

|

WE'RE HERE TO HELP.

|

ColorID has spent over 24 years serving the ID Industry with top-level sales and support to build the ultimate trust with every customer.

|

|

|

|