|

Visit ColorID at the 2014 ASIS Conference in Atlanta, GA ---- Booth 3114. Exhibit hall is open today & tomorrow ( Tuesday / Wednesday ) 9am - 3:30. We are showcasing our Identification Badge Printer line up as well as the latest in Biometric Solutions. Check out the ASIS Trade Show Planner by clicking here If you'd like to receive a free exhibit hall pass, contact us today.

0 Comments

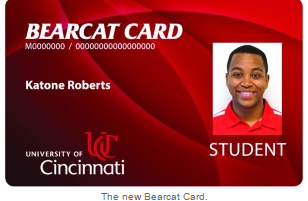

Whether to pre-print static areas of the institution's cardstock or rely on desktop printers to add all the elements on the fly is an important and debatable topic. There are tangible benefits - both in terms of the cards themselves and the process of issuing them -for a university that pre-prints its cardstock. But there are also drawbacks related to flexibility and timeliness.

ColorID's higher education & K-12 market manager, Tim Nyblom, spoke with CR80News about when pre-printing card stock is appropriate, why a university should consider it, and most importantly, how they should do it. Why pre-print? "Pre-printing is for universities that want a professional-grade cardstock and recognize that cost is not the primary concern," says Nyblom. "It creates a longer lasting card with superior color quality and provides a more robust final product than a standard desktop printer can yield." Professional aesthetics and longer lifespans aren't the only benefits, however. As Nyblom explains, pre-printing enables a university to expedite the issuance process, as there is less area for the printer to cover, allowing the ID card to be completed quicker. "Pre-printed cardstock using lithographic or digital presses is made via layers and the artwork layer is protected by a thick clear sheet of laminate," explains Nyblom. "Desktop ID printers print on the outside layer of a manufactured card and thus is prone to fading over time." Pre-printed cards offer a noticeably better print quality that cannot be matched using a desktop ID printer. "Pre-printed cardstock gives you 3,000 DPI (Dots per square inch), whereas desktop ID printers can only reach 600 DPI," he explains. "It also allows a university to utilize the Pantone Matching System to recreate their brand's specific colors." More than one way to pre-print Deciding whether or not to pre-print is just the first step. Next is choosing the printing method and whether to do the work in house or outsource to a third-party vendor.As Nyblom explains, there are three pre-printing methods that a university can choose from: lithographic printing, high definition/digital press printing, and dye sublimation. "In house pre-printing is usually done with a high issuance desktop ID printer utilizing the dye sublimation method," explains Nyblom. "This method is good when low quantities, single-sided printing or monochrome (one color) printing is needed." Nyblom stresses that the in-house method using a desktop dye sublimation printer is not to be confused with outsourcing via lithographic or digital press printing. "Once a card has passed through a desktop ID printer, you do not want to print on that same side again as the print head and ribbon can stick to the already printed cardstock," he says. In the campus card market where card fronts are almost always personalized to the individual, in-house dye sublimation pre-printing is typically only considered for static card backs as a time saving measure. This is not the case, however, with other printing methods. "Having your static design pre-printed via a lithographic or digital press first and then printing your variable information with your desktop ID printer is the best route to take," says Nyblom. Variable information often includes elements such as cardholder photo, name, ID number and barcode. Nyblom explains that lithographic printing is ideal for large quantity runs of 5,000 cards or more. The printing is of an extremely high quality, offering a 3,000 DPI resolution, and has the ability to print a large number of colors, including specific spot colors - often referred to as PMS or Pantone colors. "In this process, the cards are manufactured from large plastic sheets consisting of 28, 56 or 70 cards per sheet that are then cut down into individual cards," explains Nyblom. "The cards are built up through different layers of materials including clear plastic, PVC and PET." Another avenue is High Definition printing, otherwise known as Digital Press printing. This method is ideal for low to mid-level quantities from 500 up to 10,000 cards, while still offering up to 3,000 DPI print resolution. The main difference from Lithographic, as Nyblom explains, is that digital press plastic sheets typically consist of only 21 cards per sheet. "Universities that opt for digital press can still utilize multiple colors for their cards and incorporate Pantone colors for their unique and custom branding," he adds. While the other methods mass produce printed cardstock, dye sublimation printing is done one card at a time on pre-assembled ID cardstock, and is generally used for low-volume printing. "The dye sublimation process will apply color to the cardstock one color at a time: yellow, magenta, cyan and then black," says Nyblom. "Since this process only uses a four color process, it is not able to match PMS (Pantone) colors. It's a process that is excellent for quick turn projects, low quantities and variable printing jobs." The case against pre-printing Still, pre-printing cardstock may not always be the answer. "If a school is just launching their ID card program, I'd suggest starting off with utilizing a blank cardstock first," Nyblom says. "This will allow them to adjust and change their card design to what works for them. After the university gains more experience and has identified what matters to them, then I would suggest migrating to a pre-printed cardstock." Traditionally, the arguments against pre-printing highlighted the lack of flexibility it carries. Once a large quantity of cards is ordered and printed, changes to card design are not possible. If these changes are mandated any remaining inventory must be discarded. Additionally, inventory management becomes more crucial. If cards run out during the middle of an orientation session, it can cripple the issuance process and take weeks to replenish supplies. Finally, for small quantity issuers pre-printing may not be cost effective despite its benefits. Final thoughts Pre-printing is a great way for a university to expedite its card issuance, while also boosting the overall quality of its campus IDs. By understanding the pre-printing options that are available and the institution's specific requirements, pre-printing can offer a significant value add to campus card services. |

Categories

All

Archives

July 2020

|

WE'RE HERE TO HELP.

|

ColorID has spent over 24 years serving the ID Industry with top-level sales and support to build the ultimate trust with every customer.

|

|

|

|